Protecting Your Buried Treasure: Best Rock Shields for Pipelines

Pipelines are the lifeblood of our modern world, transporting essential resources like water, oil, and gas long distances. But these vital arteries are vulnerable to damage, especially when buried in rocky terrain. That's where rock shields come in Singhal Industries - Manufacturer of Flexible Packaging Product, acting as a crucial layer of protection for your buried treasure.

What is a Rock Shield?

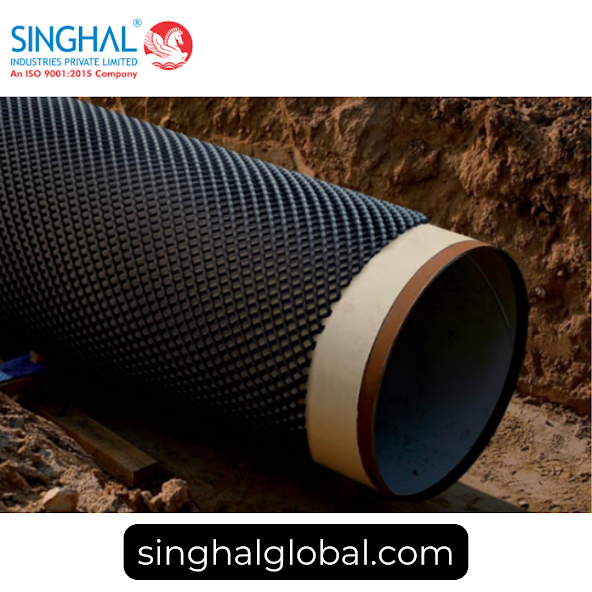

A Best rock shield is a flexible, mesh-like material, typically made from High-Density Polyethylene (HDPE), that encases pipelines during installation. It acts as a barrier between the pipe and the surrounding rocks, preventing damage from:

Impact: Sharp rocks can puncture or dent the pipe during

backfilling or due to ground movement.

Abrasion: Friction from shifting rocks can wear down the

pipe's protective coating over time.

Stress: Uneven pressure from surrounding rocks can put

stress on the pipe, leading to cracks or leaks.

Why Choose HDPE Rock Shield?

Here are some key advantages of using HDPE rock shield for your pipeline protection needs:

Durability: HDPE is known for its exceptional strength and

resistance to impact, abrasion, and harsh chemicals commonly found in soil.

Flexibility: The mesh design allows the shield to conform to

uneven surfaces and accommodate slight pipe movement without compromising

protection.

Lightweight: Compared to traditional concrete or steel

protection methods, HDPE rock shield is significantly lighter, making it easier

to handle and install.

Cost-effective: The material and installation process are

generally more affordable compared to other options.

UV resistance: High-quality HDPE shields are formulated to

withstand prolonged exposure to sunlight without degradation.

Easy installation: HDPE rock shield can be easily wrapped

around the pipe and secured with straps, making the installation process

efficient and less labor-intensive.

Choosing the Best Rock Shield:

While HDPE is the most common material for rock shields, different options may be available depending on your specific needs. Here are some factors to consider when choosing the best rock shield for your project:

Pipe diameter: Ensure the chosen shield width is suitable

for your pipe size.

Rock size and density: Consider the size and sharpness of

the rocks in the surrounding area to determine the appropriate shield

thickness.

Project requirements: Some projects may require additional

features like flame retardancy or specific UV resistance levels.

Conclusion:

Investing in a high-quality Rock shield for pipeline is crucial for

ensuring the long-term integrity and safety of your buried pipelines. By

choosing an HDPE rock shield, you can benefit from a cost-effective and

reliable solution that safeguards your valuable infrastructure for years to

come.

Frequently Asked Questions

1. What is a rock shield and why is it important for

pipelines?

A rock shield is a protective layer installed around

pipelines to shield them from damage caused by external forces, particularly

rock abrasion or impact during installation and operation. It's crucial for

maintaining the integrity and longevity of pipelines, preventing leaks, and

ensuring safe transportation of fluids.

2. How is an HDPE rock shield installed on a pipeline?

The installation process for an HDPE rock shield involves

several steps. First, the pipeline is cleaned and prepared to ensure a smooth

surface. Then, the HDPE rock shield is wrapped around the pipeline in multiple

layers, with overlaps to provide complete coverage. The shield is secured in

place using mechanical fasteners or adhesive tapes, depending on the specific

requirements of the project. Finally, the installation is inspected to ensure

proper alignment and adherence to industry standards.

3. What are the benefits of using HDPE rock shields compared

to other materials?

HDPE rock shields offer several advantages over alternative

materials for pipeline protection. Firstly, HDPE is highly resistant to

corrosion, chemicals, and UV exposure, ensuring long-term durability in harsh

environments. Additionally, HDPE rock shields are lightweight and flexible,

making them easier to handle and install compared to traditional materials like

concrete or steel. Furthermore, HDPE rock shields are environmentally friendly

and recyclable, reducing the overall ecological footprint of the pipeline

construction project.

4. How effective is an HDPE rock shield in preventing damage

to pipelines?

HDPE rock shields are highly effective in protecting

pipelines from damage caused by rocks, stones, and other external hazards. The

durable HDPE material provides a robust barrier against impacts, abrasions, and

punctures, significantly reducing the risk of leaks or ruptures in the

pipeline. Additionally, the flexibility of HDPE rock shields allows them to

conform to the contours of the pipeline, ensuring complete coverage and maximum

protection along the entire length of the pipeline.

Comments

Post a Comment